Welcome! |

Sealing technology & technical plastics

A secure sealing of machines and equipment is always a special challenge. Our range of products in the field of sealing technology is focused on the demands of the latest technologies.

We meet the highest requirements in the production of seals, in the elastomer and foam industry as well as in the plastics technology. We offer an entire service package with high quality and innovative solutions. Special designs are made according to specific customer requirements.

Seals

Due to the high demands which are made on the safety of sealing compounds and the currently valid requests for highest leak-tightness it is necessary to have the appropriate know-how in choosing and installing the right seals.

There are whole series of demands which are made on flat gasket materials as well as the entire flange coupling to provide a reliable sealing compound.

· Adaption to the irregularities of the sealing surface

· Resistance against the medium to be sealed

· Strength of the sealing compound

· Leak-tightness

· The maximum allowable surface pressure

· Required gasket thickness

· Use in the low temperature range

Conventional qualities

· Rubber-bounded aramid fiber

· PTFE

· Graphite

· Rubber

Conventional processing methods

· Cutting

· Milling

· Punching

· Plotting

· Water jets

Plastics

Plastic products are used in various industrial sectors. For example, they are found in the food industry as cutting boards, as storage boxes for chemical media or process boxes in the chemical apparatus and tank construction, as ventilation systems in the semiconductor and clean-room technology or as sliding and conveying component in the packing and beverage industry, as large-volume insulation components in the transformer or generator construction or as a storage tank supporting the transport of liquefied gases.

Common qualities

· Polyethylene (PE)

· Polycarbonate (PC)

· Acrylic glass

· PTFE

· Polyurethane (PUR)

· Polyamide (PA)

· Polyoxymethylene (POM)

· PVC

Conventional processing methods

· Cutting

· Milling

· Plotting

Elastomer and foam technology

Elastomer and foam products are used in almost all sectors of daily life, for example in the automotive industry, appliance industry, shipbuilding, tank and container construction as well as in the machine and plant construction. They are mainly used for sealing, insulating and protecting.

Common qualities

· NBR, SBR, EPDM, CR

· Viton

· Silicon

· Flexible polyurethane foam

· PE foam

· Accoustic insulation foam

· Melamine resin foam

Conventional processing methods

·Laminating

·Plotting

·Cutting

·Punching

We can assure our customers just-in-time deliveries for many commercial sealing materials. This has proved itself especially in case of shutdowns and overhauls.

Sealing technology

- Graphite seals

- Fiber seals

- Elastomer seals

- Flange seals

- Plastic seals

- Grooved metal gasket

- Seals made of cellular materials

- Sealing tapes and profiles

- Thermoplastics and thermosets

- O-rings and moldings

- DIN-rings

- Frame seals

- Flanges

- Standard seals

- Sealing strips

- Special seals

- Hatch seals

- Manhole seals

- Spiral wound gasketsSealing technology

Elastomer and foam technology

- Para rubber

- Viton

- Cell polyurethane

- Foam rubber

- Silicone

- Polyethylene foam

- Polyurethane

- Cellular rubber

- Acoustic foam and silicone

- PUR-flexible foam

- Rubber

- Profiles and strips of solid and foamed materials

- Asphaltic material

- Scrapers

- Impact protection

- Insulating boards

- Cuffs

- Container applications

- Funnel lining

- Draw rolls

- Distance pieces

- Foam inserts

Contact us:

Office +234 (0)8100172923

Mobile +234 (0)8023134941

sales@nigeriaindustrialMROsupply.com

|

|

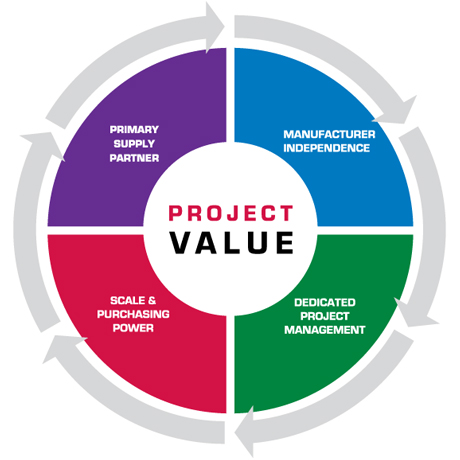

Projects

| Made in USA Products

We source direct from OEM | Official Nigerian Distributor

.jpg?template=generic)   |

Quality MRO & OEM Industrial SuppliesNigerian Downstream oil and gas producers rely on us for MRO needs.MRO Supplies - Maintenance, Repair and Operation (MRO) items are used in production and plant maintenance and can be items such as maintenance supplies, spare parts, Safety Supplies and consumables used in the production process. This includes items such as: oils, lubricants, gloves, safety equipment and cleaning products.

| Services

|

We continually strive to be a great company. Metalworth Resources Ltd is committed to providing high-quality products and services to our customers.

For Urgent Enquiries Please contact :

sales@nigeriaindustrialMROsupply.com or maintenance@metalworth.net

Tel: +23480231349421, +2348051609891